Latest Technologies and Developments A specialist focuses on a topic, knows its past, knows everything about the current situation and has ideas about the future. MoPipe is such a specialist. Fabrication of high quality products is impossible without investing in quality on all fronts. MoPipe possesses over the latest welding technology and uses new techniques in the prefabricated shop, ensuring high quality and speed. The welding at MoPipe is carried out by certified welders. Our employees apply the NEN-EN-ISO 9606-1 / ISO 9606-2, ASME IX and AD2000 HP-3 Merkblätt standards. We have these certifications for both hand welding and automated welding. Quality features

Lloyd's, TÛV and Det Norske Veritas (DNV) certified welders with the following certifications;

The system applies to all processes within our company. This offers the guarantee that the final product satisfies the wishes of our customers.The prefabricated material is approved and tested in the prefabricated shop, and if needed, stored. MoPipe has several storage possibilities;

Regular Renewal Machine Park MoPipe possesses over the most modern welding machines for her specialty welding. Advantages:

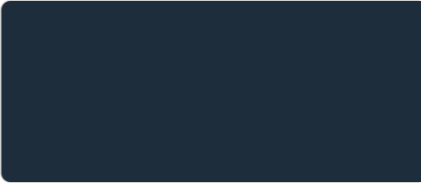

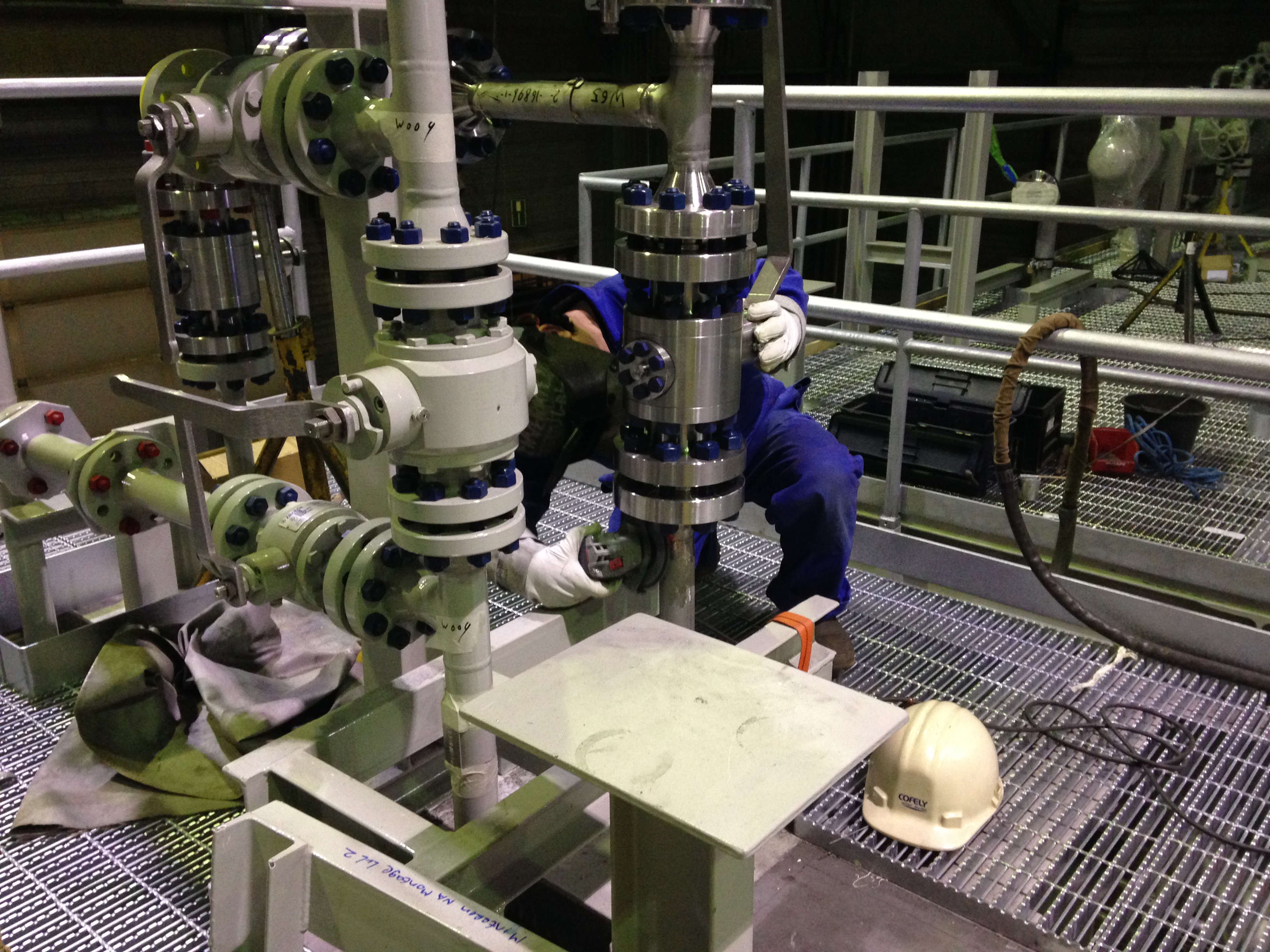

The machines use the latest developments and ensure that the welding process can be carried out to perfection. For the sawing of profiles, we have the modern full-automatic band saw Behringer H-frame. We possess over a pipe beveller for the beveling of pipes. Consequently, the above allows us to ensure the quality of the welds according to the norm. Experience MoPipe has developed itself as a specialist in the petrochemical industry, due to years of working experience. Maintenance and Reparations Through the years, MoPipe has developed itself in maintenance works. All employees are VCA certified and own a lift truck license. Welding is always performed by a certified welder. This department installs and maintains the products and installations which are fabricated and delivered by MoPipe, as well as installations which the customer wishes to be carried out by MoPipe. In consultation with the customer, based on a pre-established maintenance plan and an open calculation, all occurring maintenance works are analyzed and carried out. |

Are you looking for an organization with years of experience? Then you are at the right address with MoPipe’s services. We are able to work at our own workplace, as well as on location. These options allow for decisions on the most efficient procedure. When you choose for MoPipe’s services, you choose for quality and efficiency. We make sure that revision activities are finalized as expected, and that overdue maintenance does not have a chance. |

phone. +31 (0)40 844 9694 | fax. +31 (0)40 848 1451